- Solid liquid separator

- 【Brief】:

Solid-liquid separator :

The equipment is mainly suitable for paper mill pulp and food industry if slag, potato dregs, starch residue, bagasse, tea residue, soy sauce and other dehydration treatment, solid-liquid separation of biogas residue in environmental protection project, dewatering treatment of dust removal sludge, brewing enterprise Solid-liquid separation of beer lees, vinegar residue, white distiller's grains, livestock and poultry manure such as cow dung, pig manure, chicken manure, duck manure, solid-liquid separation and dehydration, and solid-liquid separation of artificial board wastewater.

- 【Series】:Dryer

First, the introduction

The working principle of the solid-liquid separator is to separate the solid and the liquid by the screw press. The liquid to be treated enters the screw slag machine through the pipe or the funnel, firstly dewaters by the first-stage gravity, and the dehydration is uniformized by a vibration device. The initially dehydrated material forms a filter layer on the surface of the sieve plate, which is continuously peeled off from the surface of the sieve by the spiral and sent to the subsequent extrusion dewatering portion to form a plug, and the friction between the stopper and the inner wall ensures the working pressure. A variable weight mechanical device provides a reverse pressure to adjust the concentration of the dewatered material.

The spiral solid-liquid separator can be made of stainless steel and cast iron, with a power of 4Kw to 30Kw and a processing capacity of 5 to 350m3, that is, 10 to 50 tons of dry solids. And easy to install and maintain.

The amount of solids in the influent water is less than 1mm, and the screw slag crusher can handle substances larger than 20mm. The separated solid has a dry matter content of more than 65% and a grid slit size of 0.1 mm to 1.0 mm.

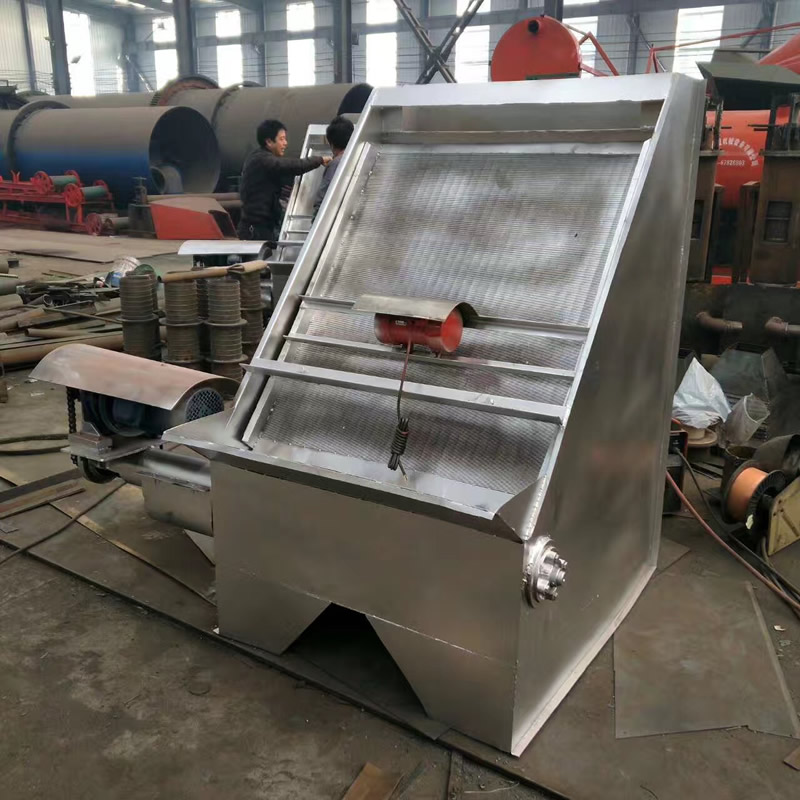

Slant screen pig manure dewatering machine

Second, the application area

1. Dehydration of materials (putting on the slag remover, sieve, fiber classifier, and processing waste);

2. Purification of wastewater;

3. Fiber recycling;

4. Separating non-stick objects;

5. Sludge flotation, sludge deposition.

Slant screen pig manure dewatering machine

Solid-liquid separator structure

Main parameters

|

Model |

20m³ |

40m³ |

60m³ |

|

Main power (KW) |

4 |

4 |

5.5 |

|

Process capacity (m³/h) |

20-25 |

35-40 |

55-60 |

|

Dimension(mm) |

1950x1200x1600 |

2300x1250x1650 |

2450x1300x1750 |

|

Construction material |

Sus304 |

Sus304 |

Sus304 |

|

Accessories |

Mixer,cut pump, control cabin, steel wire soft hose, PVC return valve |

Mixer,cut pump, control cabin, steel wire soft hose, PVC return valve |

Mixer,cut pump, control cabin, steel wire soft hose, PVC return valve |

|

Pump power(KW) |

3 |

3 |

4 |

|

Mix power(KW) |

3 |

3 |

3 |

|

Vibration power |

30W |

60W |

60W |

QR Code

QR Code