The equipment produced by our company is mostly general-purpose equipment, suitable for tens of thousands of materials in various industries, considering the different characteristics of each material, our company has designed a variety of strips for various types of equipment, and choose the best solution according to the characteristics of the material, which may be a single equipment or a variety of equipment to complete the operation. Over the years, our company has actually tested thousands of materials, and has accumulated rich experience through trial machines and communication with users in various industries. You can choose equipment, build production lines or design products for you, please communicate with our professional customer service.

Device features

The equipment does not produce high temperature and the pressure is adjustable during granulation, and will not cause the starch to mature and harden after pressing due to high mechanical pressure or high temperature, and the phenomenon does not melt when exposed to water. Luo operation elasticity, particle size, shape, hardness can be adjusted.

The equipment is made of high-quality stainless steel materials and sanitary seals, which will not cause contamination to the materials and fully meet the food and pharmaceutical standards.

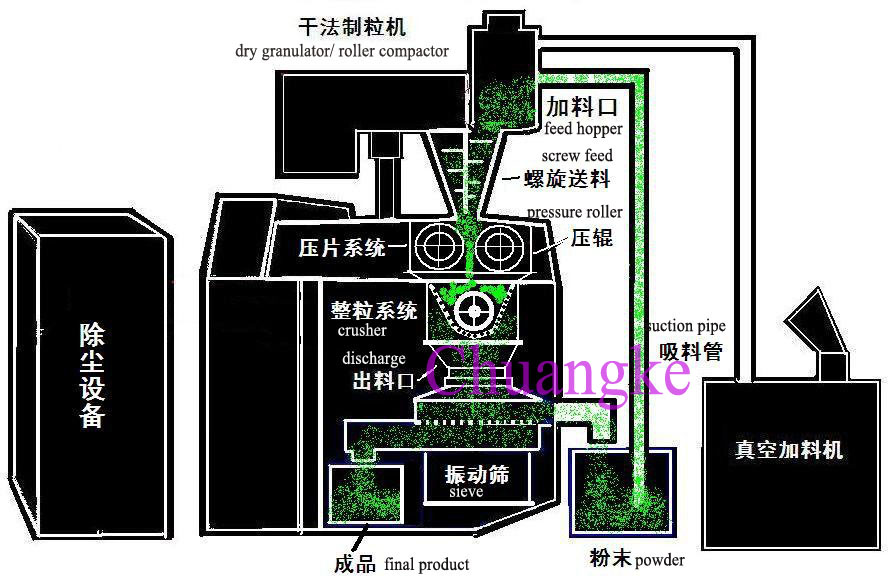

The dry powder is directly compressed and formed by high pressure, without adding water, adhesives or wetting agents, without subsequent drying, without destroying the chemical properties of the material, without reducing the effective content of the product, and the purity of the product is guaranteed. Fully automated continuous operation, simple and convenient operation, less staffing, low production cost input.

The whole set of equipment structure is closed-cycle, which avoids the phenomenon of dust flying, so as not to cause environmental pollution and raw material loss in the workshop.

Compact structure, convenient maintenance, simple operation, short process flow, low energy consumption, high efficiency and low failure rate.

Equipment selection

Our dry granulator has A type and B type two models, each model has a size model optional, users can choose the model according to their own production demand, if the output of a single equipment can not meet your needs, can use multiple equipment to form a large production line production

Small-medium size machine parameter (A)

|

Model |

50 |

80 |

100 |

120 |

150 |

200 |

300 |

400 |

|

Capacity(kg/h) |

7-10 |

10-50 |

30-80 |

40-100 |

80-150 |

100-300 |

200-800 |

300-1200 |

|

Hopper (L) |

3 |

6 |

7 |

8 |

10 |

15 |

30 |

50 |

|

Roller pressure(kn/cm) |

65 |

65 |

65 |

65 |

65 |

65 |

65 |

65 |

|

Roller speed(rpm) |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

|

Feed speed(rpm) |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

1-50 |

|

Total power (KW) |

5.95 |

11 |

13 |

13 |

16.5 |

27.3-31.8 |

34.1-42.1 |

57-76.1 |

|

Weight(t) |

1 |

1.8 |

2 |

2.1 |

2.5 |

2.8 |

3 |

4 |

|

Dimension (m) |

1.2x0.7x1.7 |

1.6x1x2.1 |

1.6x1.1x2.2 |

1.6x1.2x1.3 |

1.7x1.3x2.6 |

2.4x1.4x3 |

2.6x1.6x3.8 |

2.8x1.8x4 |

Medium-large size machine parameter (B)

|

Model |

LM-240 |

LM-360 |

LM-450 |

LM-500 |

LM-600 |

LM-650 |

|

Roller dia.(mm) |

Ø240 |

Ø360 |

Ø450 |

Ø504 |

Ø600 |

Ø650 |

|

Effective length(mm) |

80/120/160 |

180 |

190-280 |

300 |

310 |

330 |

|

Roller speed(RPM) |

5-35 |

3-26 |

14-20 |

14-20 |

12-18 |

10-16 |

|

Feeder power(KW) |

4 |

7.5 |

11 |

11 |

11 |

15 |

|

Prepress (MPa) |

5 |

6 |

8-10 |

8-10 |

8-10 |

10-14 |

|

Max. Form pressure(kn/cm) |

65 |

65 |

70/75 |

70/75 |

70/75 |

70/75 |

|

Press case thickness(mm) |

2-6 |

6-8 |

10-12 |

10-12 |

12-14 |

14-16 |

|

Cake output (t/h) |

0.8-2 |

1.5-2.5 |

2.5-3.5 |

3-5 |

5-7 |

10-12 |

|

Set output(t/h) |

0.2-0.6 |

1-1.5 |

2.5-3 |

2.5-3 |

3-3.6 |

3.5-4.5 |

|

Product size(mm) |

1-5 |

0.5-1.5 |

0.8-2 |

2-5 |

2.5-6 |

3-7 |

|

Main machine power (KW) |

11 |

30 |

55-75 |

75-90 |

90-110 |

175 |

|

Total power(KW) |

35 |

55 |

90 |

109 |

125 |

165 |

|

Main machine dimension(m) |

1.9x1.5x1.7 |

2.4x2x2.4 |

3.6x2.3x2.5 |

3.6x2.3x2.5 |

3.6x2.5x2.7 |

4x2.6x3.3 |

|

Main machine weight(t) |

3 |

6 |

10 |

15 |

20 |

25 |

QR Code

QR Code